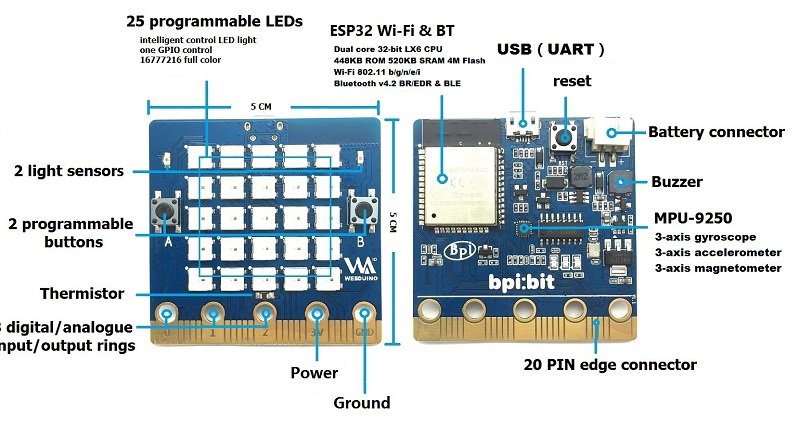

In this article we look the MPU-9250 Nine-Axis (Gyro + Accelerometer + Compass) MEMS MotionTracking™ Device which is fitted to the BPI:bit

webduino:bit

The sensor uses the following GPIO

| MPU9250_SCL | GPIO 22 | Digital Output |

| MPU9250_SDA | GPIO 21 | Digital Output |

| MPU9250_INT | GPIO 16 | Digital Input |

Parts Required

| Name | Link |

| Banana PI Bit board | Banana PI Bit board with EPS32 |

$19.50 for this board is a good price

Features

Lets look at the sensor features from the manufacturer

Gyroscope Features

The triple-axis MEMS gyroscope in the MPU-9250 includes a wide range of features:

- Digital-output X-, Y-, and Z-Axis angular rate sensors (gyroscopes) with a user-programmable full-scale range of ±250, ±500, ±1000, and ±2000°/sec and integrated 16-bit ADCs

- Digitally-programmable low-pass filter

- Gyroscope operating current: 3.2mA

- Sleep mode current: 8μA

Accelerometer Features

The triple-axis MEMS accelerometer in MPU-9250 includes a wide range of features:

- Digital-output triple-axis accelerometer with a programmable full scale range of ±2g, ±4g, ±8g and ±16g and integrated 16-bit ADCs

- Accelerometer normal operating current: 450μA

- Low power accelerometer mode current: 8.4μA at 0.98Hz, 19.8μA at 31.25Hz

- Sleep mode current: 8μA

- User-programmable interrupts

- Wake-on-motion interrupt for low power operation of applications processor

Magnetometer Features

The triple-axis MEMS magnetometer in MPU-9250 includes a wide range of features:

- 3-axis silicon monolithic Hall-effect magnetic sensor with magnetic concentrator

- Wide dynamic measurement range and high resolution with lower current consumption.

- Output data resolution of 14 bit (0.6μT/LSB) or 16 bit (15μT/LSB)

- Full scale measurement range is ±4800μT

- Magnetometer normal operating current: 280μA at 8Hz repetition rate

- Self-test function with internal magnetic source to confirm magnetic sensor operation on end products

Additional Features

The MPU-9250 includes the following additional features:

- Auxiliary master I2C bus for reading data from external sensors (e.g. pressure sensor)

- 3.5mA operating current when all 9 motion sensing axes and the DMP are enabled

- VDD supply voltage range of 2.4 – 3.6V

- VDDIO reference voltage for auxiliary I2C devices

- Smallest and thinnest QFN package for portable devices: 3x3x1mm

- Minimal cross-axis sensitivity between the accelerometer, gyroscope and magnetometer axes

- 512 byte FIFO buffer enables the applications processor to read the data in bursts

- Digital-output temperature sensor

- User-programmable digital filters for gyroscope, accelerometer, and temp sensor

- 10,000 g shock tolerant

- 400kHz Fast Mode I2C for communicating with all registers

- 1MHz SPI serial interface for communicating with all registers

- 20MHz SPI serial interface for reading sensor and interrupt registers

Code

You can roll your own code but I chose a library in the Arduino library manager called the MPU9250_asukiaaa

This is one of the default code examples

[codesyntax lang=”cpp”]

#include <MPU9250_asukiaaa.h>

#ifdef _ESP32_HAL_I2C_H_

#define SDA_PIN 21

#define SCL_PIN 22

#endif

MPU9250_asukiaaa mySensor;

float aX, aY, aZ, aSqrt, gX, gY, gZ, mDirection, mX, mY, mZ;

void setup() {

Serial.begin(115200);

while(!Serial);

Serial.println("started");

#ifdef _ESP32_HAL_I2C_H_ // For ESP32

Wire.begin(SDA_PIN, SCL_PIN);

mySensor.setWire(&Wire);

#endif

mySensor.beginAccel();

mySensor.beginGyro();

mySensor.beginMag();

// You can set your own offset for mag values

// mySensor.magXOffset = -50;

// mySensor.magYOffset = -55;

// mySensor.magZOffset = -10;

}

void loop() {

uint8_t sensorId;

if (mySensor.readId(&sensorId) == 0) {

Serial.println("sensorId: " + String(sensorId));

} else {

Serial.println("Cannot read sensorId");

}

if (mySensor.accelUpdate() == 0) {

aX = mySensor.accelX();

aY = mySensor.accelY();

aZ = mySensor.accelZ();

aSqrt = mySensor.accelSqrt();

Serial.println("accelX: " + String(aX));

Serial.println("accelY: " + String(aY));

Serial.println("accelZ: " + String(aZ));

Serial.println("accelSqrt: " + String(aSqrt));

} else {

Serial.println("Cannod read accel values");

}

if (mySensor.gyroUpdate() == 0) {

gX = mySensor.gyroX();

gY = mySensor.gyroY();

gZ = mySensor.gyroZ();

Serial.println("gyroX: " + String(gX));

Serial.println("gyroY: " + String(gY));

Serial.println("gyroZ: " + String(gZ));

} else {

Serial.println("Cannot read gyro values");

}

if (mySensor.magUpdate() == 0) {

mX = mySensor.magX();

mY = mySensor.magY();

mZ = mySensor.magZ();

mDirection = mySensor.magHorizDirection();

Serial.println("magX: " + String(mX));

Serial.println("maxY: " + String(mY));

Serial.println("magZ: " + String(mZ));

Serial.println("horizontal direction: " + String(mDirection));

} else {

Serial.println("Cannot read mag values");

}

Serial.println("at " + String(millis()) + "ms");

Serial.println(""); // Add an empty line

delay(500);

}

[/codesyntax]

Output

Here is an example of my output

sensorId: 113

accelX: -0.06

accelY: -0.08

accelZ: 1.04

accelSqrt: 1.04

gyroX: 0.67

gyroY: -0.49

gyroZ: -0.55

magX: 95.13

maxY: 8.12

magZ: -105.38

horizontal direction: 85.12

at 102570ms

Links

https://www.invensense.com/products/motion-tracking/9-axis/mpu-9250/

https://www.invensense.com/download-pdf/mpu-9250-datasheet/